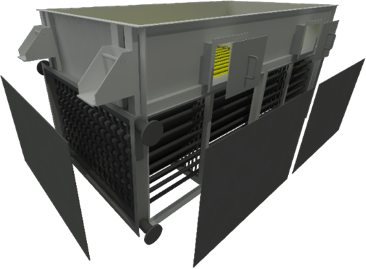

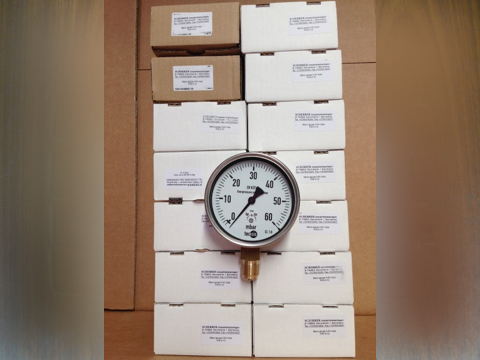

DESULFURIZING UNIT

DESULFURIZING UNIT

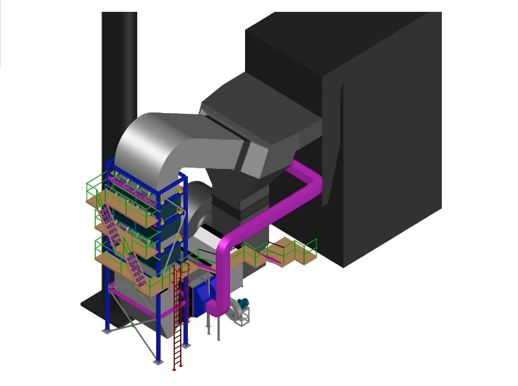

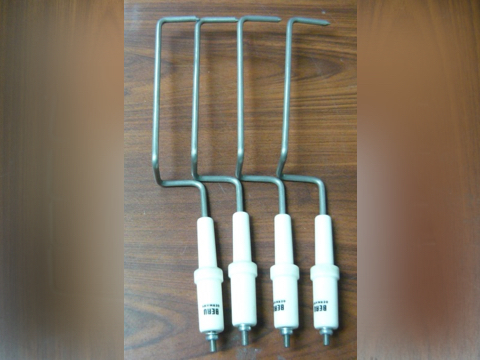

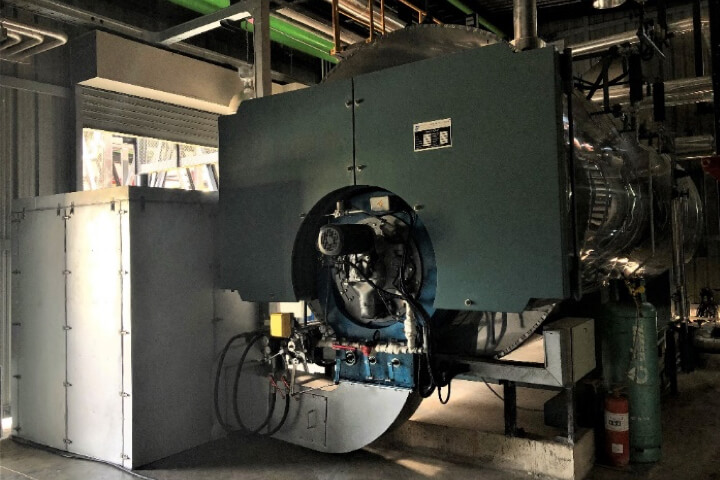

FLARE SYSTEM

FLARE SYSTEM

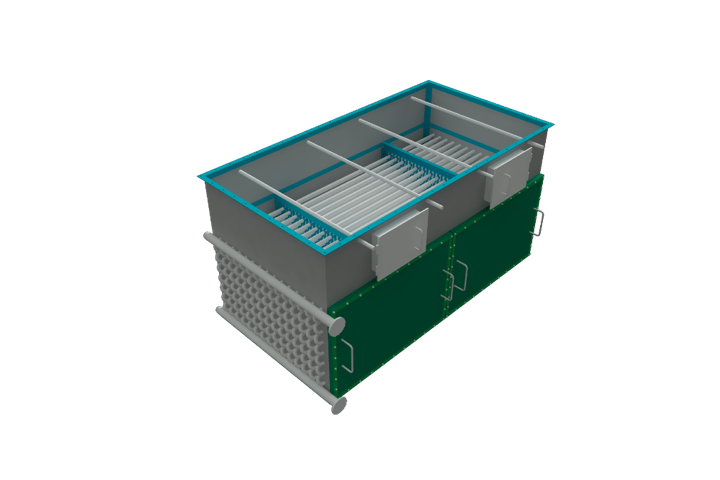

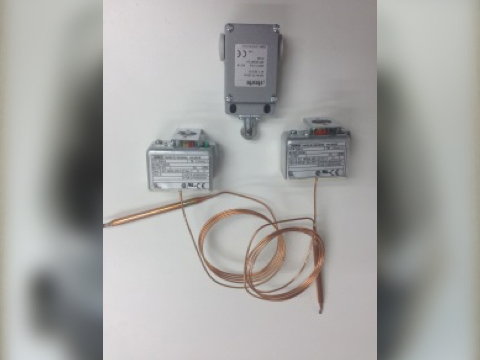

KNOCK OUT DRUM

KNOCK OUT DRUM

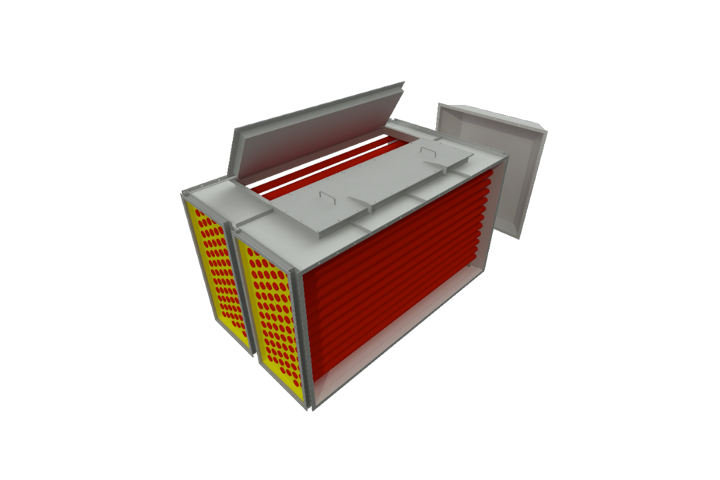

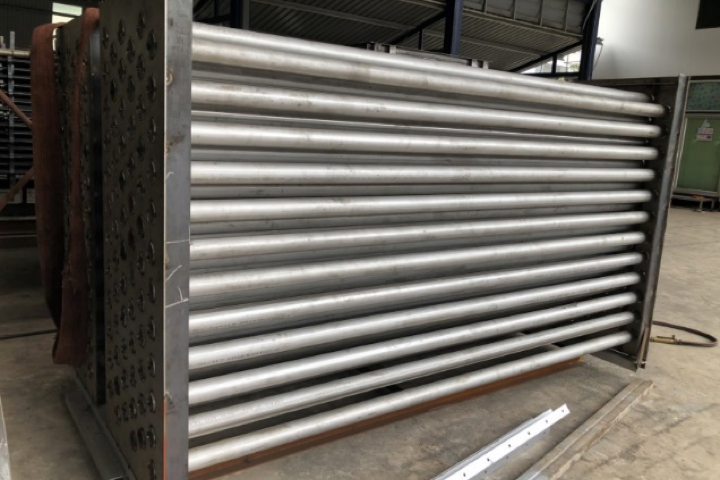

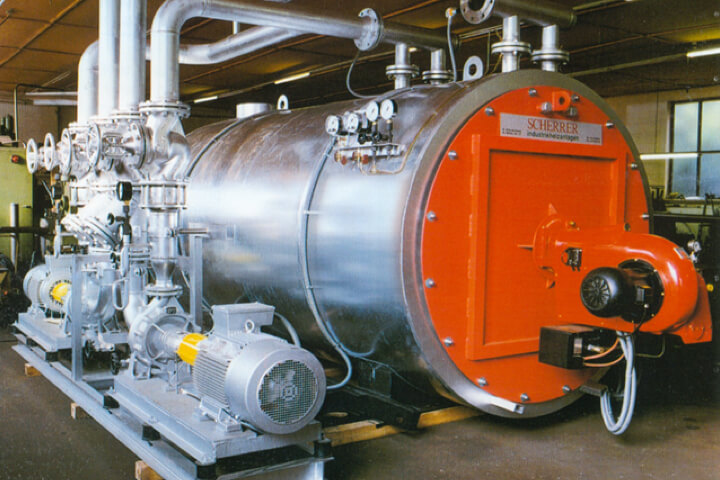

BIOGAS COOLER

BIOGAS COOLER